Hunan Fortune welcomes you!

CAS 1429-50-1 EDTMPA Ethylene Diamine Tetra (Methylene Phosphonic Acid)

Category:

CAS No.: 1429-50-1

Formula: C6h20n2o12p4

Product Introduction

Product Description

Product Name: Ethylene Diamine Tetra (Methylene Phosphonic Acid) (EDTMPA)

CAS Number: 1429-50-1

Molecular Formula: C6H12O12N2P4Na8 (as sodium salt, EDTMPS)

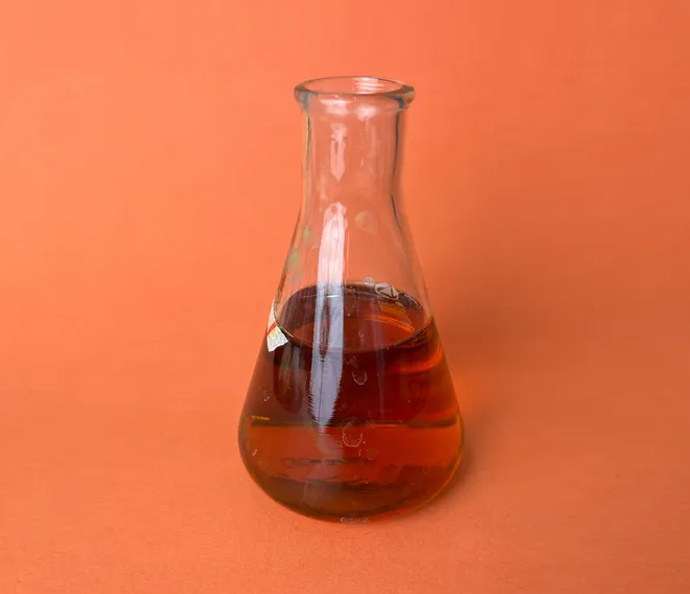

Appearance: Yellow to brown transparent liquid

Density: ≥ 1.25 g/cm³ (at 20°C)

pH: Alkaline (pH 9.5-10.5 in 1% aqueous solution)

Solubility: Highly soluble in water

Product Description: EDTMPA is a potent chelating agent used primarily in water treatment processes to prevent scale formation and corrosion. The compound is based on an ethylene diamine backbone with four methylene phosphonic acid groups, providing it with high affinity for metal ions.

Applications:

Water Treatment: Utilized in both industrial and domestic water treatment to prevent scale and corrosion.

Cooling Systems: Effective in closed-loop cooling systems to manage scale and corrosion.

Boiler Water Treatment: Enhances boiler efficiency by preventing scale build-up.

Reverse Osmosis: Employed to prevent scale formation in membrane systems.

Detergents and Cleaners: Used to enhance cleaning performance and stability.

Key Features:

High Chelating Capacity: Forms stable complexes with metal ions, preventing scale formation.

Environmental Compatibility: Considered environmentally friendly with low toxicity and high biodegradability.

Wide pH Stability: Effective over a broad pH range, suitable for various water conditions.

Safety Information:

Handle with appropriate personal protective equipment (PPE), including gloves, safety goggles, and a mask.

Avoid contact with skin and eyes. In case of contact, flush immediately with plenty of water and seek medical advice if necessary.

Storage Conditions:

Store in a cool, dry, and well-ventilated area away from direct sunlight and heat sources.

Keep containers tightly sealed to maintain product integrity and prevent contamination.

Regulatory Information:

EDTMPA complies with international standards and regulations for use in its specified applications.

|

Active content (as acid)% |

25%min |

|

Phosphorous acid(as PO33-) % |

1.0max |

|

Phosphoric acid(as PO43-)% |

6.0-12.0 |

|

PH(1% solution) |

4.0max |

|

Density(20ºC) g/cm3 |

1.10 |

|

Appearance |

colorless to pale yellow transparent liquid |

|

|

|

Packed in kraft paper or PE bags with inner plastic flim bags.

25kgs/bag,1000kg/palllet,40bags/pallet.

Company Profile:

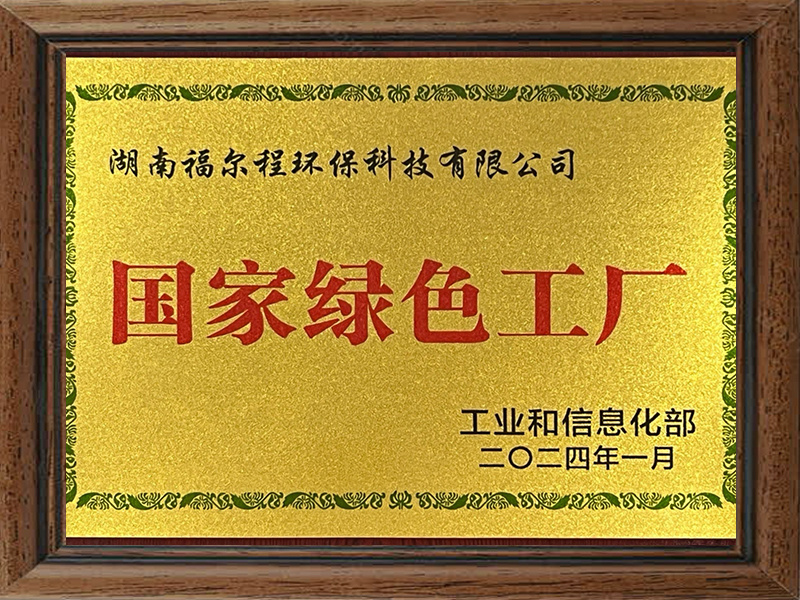

Hunan Fortune Technology Co., Ltd., established in 2004 and officially registered in 2016 with a 30 million RMB capital, is a leading provider of fine chemicals with nearly two decades of industry experience. Based in Zhuzhou, our company specializes in research and production of high-quality chemical agents, including mining chemicals, for environmental solutions and metallurgical processes.

Our team of chemical engineers, with over 20 years of metallurgical expertise, ensures we offer customized solutions and premium products to meet diverse client needs. We have expanded our services to include mining chemicals, enhancing efficiency and sustainability in the mining sector.

With a strong commitment to innovation and sustainability, Hunan Fortune Technology Co., Ltd. is dedicated to providing effective and reliable environmental solutions, contributing to a greener future.

|

|

|

Technical Support:

|

|

Water treatment chemicals play a critical role in ensuring the safety, efficiency, and longevity of water systems across industrial, commercial, and municipal sectors. These chemicals are designed to control and prevent a range of water-related issues, including scale formation, corrosion, microbial growth, and turbidity, while maintaining water quality within the required regulatory standards. The global demand for water treatment chemicals continues to rise as industries expand and environmental regulations become increasingly stringent.

Industrial water systems, such as cooling towers, boilers, and manufacturing processes, require precise chemical management to maintain operational efficiency. Scale formation, caused by the precipitation of calcium, magnesium, and other minerals, can significantly reduce heat transfer efficiency and increase energy consumption. Water treatment chemicals, including phosphonates, polycarboxylates, and dispersants, prevent scale deposition, ensuring smooth operation and reducing maintenance costs.

Corrosion control is another vital aspect of water treatment. Metals used in piping, heat exchangers, and storage tanks are susceptible to oxidation and chemical attack, which can lead to leaks, equipment failure, and downtime. Corrosion inhibitors, such as azoles and metal passivators, form protective layers on metal surfaces, extending the life of equipment and maintaining system integrity. By combining scale inhibitors and corrosion control agents, comprehensive water treatment programs can protect infrastructure while optimizing operational performance.

Microbiological growth in water systems, including bacteria, algae, and fungi, poses significant risks to both human health and equipment performance. Biocides, including oxidizing agents like chlorine, bromine, and non-oxidizing biocides, are used to control microbial populations and prevent biofilm formation. Effective microbial control ensures the safety of potable water supplies and prevents fouling in industrial systems, which can impair heat exchange and reduce efficiency.

The versatility of water treatment chemicals extends to wastewater management and environmental protection. Coagulants and flocculants are used to remove suspended solids, turbidity, and colloidal particles from wastewater before discharge or reuse. These chemicals enhance sedimentation, reduce chemical oxygen demand (COD), and improve overall water clarity. Additionally, pH adjusters and neutralizers ensure that treated water meets environmental discharge standards, reducing the impact of industrial effluents on natural water bodies.

Water treatment chemicals are also essential in the food, beverage, and pharmaceutical industries, where water purity directly affects product quality and safety. Softening agents, dechlorination chemicals, and specialty additives ensure that process water meets stringent purity requirements, preventing contamination and maintaining product consistency.

Modern water treatment programs often rely on a combination of chemical and physical methods, including filtration, membrane separation, and ultraviolet disinfection. Chemical additives complement these technologies, providing additional protection against scale, corrosion, and microbial contamination. The synergy between chemicals and mechanical systems ensures optimized performance, reduced downtime, and cost-effective operation.

From a formulation perspective, water treatment chemicals must be compatible, stable, and easy to handle. Liquid or powdered formulations allow flexibility for different operational needs, while proper dosing and monitoring ensure maximum efficiency and safety. Environmental considerations are increasingly important; many water treatment chemicals are designed to be biodegradable, non-toxic to aquatic life, and compliant with global regulatory standards, supporting sustainable water management practices.

In summary, water treatment chemicals are indispensable in maintaining the functionality, safety, and efficiency of water systems. They prevent scale, corrosion, and microbial growth, ensure regulatory compliance, and contribute to environmental protection. Their applications span across industrial water systems, municipal water treatment, wastewater management, and high-purity water processes in specialized industries. By implementing effective chemical treatment programs, industries can achieve reliable performance, reduce operational costs, and extend the life of their water infrastructure.

Key Features of Water Treatment Chemicals:

-

Scale inhibition for boilers, cooling towers, and pipelines

-

Corrosion control for metals such as steel, copper, and aluminum

-

Microbial growth prevention using biocides and disinfectants

-

Wastewater clarification through coagulants and flocculants

-

pH adjustment and neutralization for regulatory compliance

-

Compatibility with other treatment methods, including filtration and membrane systems

-

Environmentally responsible and biodegradable formulations

Applications:

-

Industrial water systems (cooling towers, boilers, heat exchangers)

-

Municipal water treatment plants

-

Wastewater treatment and effluent management

-

Food and beverage processing water purification

-

Pharmaceutical and high-purity water production

-

Textile, paper, and chemical industry water management

Water treatment chemicals remain a cornerstone of modern water management, providing reliable, efficient, and environmentally responsible solutions for industrial, commercial, and municipal needs. By selecting the right chemicals and implementing professional treatment programs, businesses can ensure the longevity of their equipment, the safety of their water supplies, and the sustainability of their operations.

Production strength

Key words:

Fortune、chemicals

Online consultation

Filling in your phone and email information will help us get in touch with you in a timely manner and resolve your issue as soon as possible.

Related Products

![CAS 5995-42-6 HEMPA [[(2-hydroxyethyl)imino]bis(methylene)]bisphosphonic acid CAS 5995-42-6 HEMPA [[(2-hydroxyethyl)imino]bis(methylene)]bisphosphonic acid](https://omo-oss-image.thefastimg.com/portal-saas/pg2024092717483878973/cms/image/c3603fb6-9fba-45f6-94a0-da817870459e.jpg)