Hunan Fortune welcomes you!

Scaleboard Lining Board Semi-Autogenous Mill Optimization System

Category:

After-sales Service: 10 Years

Certification: CE, RoHS, ISO 9001:2000, ISO 9001:2008

Product Introduction

Basic Info.

| Model NO. | FEC | Standard | AISI, ASME, BS, ANSI, GB, GOST,ASTM, DIN |

| Surface Treatment | Polishing | Manufacturing Process | Forging |

| Material | Alloy Steel | Specification | Customized |

| Trademark | Fortune | Origin | China |

| Production Capacity | 165000 |

Product Description

Grinding equipment is the key equipment in the preparation of the dressing process. Its investment cost accounts for more than 60% of the total investment of the concentrator, and the operating cost accounts for 65%~70% of the concentrator. With the development of grinding equipment towards the direction of large and intelligent, there are more and more problems arising from the self-grinding machine in concentrators, such as the actual output is not as expected, the service life of lining plate is short, and the high consumption of steel ball. We do not do semi-self grinding machine, only do supporting consumables (lining plate) and wisdom grinding system. The teams research mainly consists of three parts: semi-grinding wear theory and algorithm research, lining design and manufacturing, and grinding software.

The core technology comes from the semi-self-grinding research team of Central South University. We have accumulated algorithm and experience for nearly 10 years, and have made achievements in two mines to solve the actual demand in the production process of the concentrator and create great economic benefits. Get the full trust of the owner and take the initiative to recommend us to other brother mines. Recently, a foreign mine is not satisfied with the products of the existing suppliers, so it took the initiative to find us and gave us the optimization task of two large semi-self machines. We have signed a contract.

SABC grinding process of a copper dressing plant, Φ8.53×3.96m large semi-self-mill has obvious particle "empty hit" lining plate burst sound in the production, the lining plate often cracks, and the service life of the lining plate is about 2.8 months. We optimized the semi-self-grinder, and the optimized grinding efficiency, lining plate life and steel ball consumption were all reduced.there are mainly: Cost reduction: reduce the lining plate consumption + power consumption (5%~8%, about 400kw / h) + steel consumption (steel ball diameter reduced from 200 to 130mm). Less shutdown: reduce the time of shutdown for maintenance and liner plate change for> 5 days. Production capacity: increased from 11,000 tons to 13,000 tons / day. Increase in output value: According to the comprehensive effect of the actual improvement, the mill reduces the cost and increases the net profit of the concentrator by> 100 million yuan every year.

Dodecylamine, with the CAS number 124-22-1, is an organic compound that is widely used as an intermediate in the synthesis of a variety of chemical products. It is recognized for its long aliphatic chain and amine group, which confer amphiphilic properties to the molecule.

|

shell liner |

Processing capacity (ball path) |

Steel consumption |

Downtime frequency |

Linear life |

power |

confluent |

|

Before optimization |

11,000 t / day (200mm) |

13 Tons / day |

15 days (check liner breakage) |

About 3 months |

About 4,600 kw |

110m³/h |

|

The first optimization |

11,000 tons / day (150mm) |

8 Tons / day |

30 days (planned downtime maintenance) |

About 4.5 months |

About 4,600 kw |

110m³/h |

|

Secondary optimization |

13,000 tons / day (130mm) |

7 Tons / day |

30 days (planned downtime maintenance) |

About 5 months |

About 4,300 kw |

80m³/h |

Company Profile:

Hunan Fortune Technology Co., Ltd., established in 2004 and officially registered in 2016 with a 30 million RMB capital, is a leading provider of fine chemicals with nearly two decades of industry experience. Based in Zhuzhou, our company specializes in research and production of high-quality chemical agents, including mining chemicals, for environmental solutions and metallurgical processes.

Our team of chemical engineers, with over 20 years of metallurgical expertise, ensures we offer customized solutions and premium products to meet diverse client needs. We have expanded our services to include mining chemicals, enhancing efficiency and sustainability in the mining sector.

With a strong commitment to innovation and sustainability, Hunan Fortune Technology Co., Ltd. is dedicated to providing effective and reliable environmental solutions, contributing to a greener future.

|

|

|

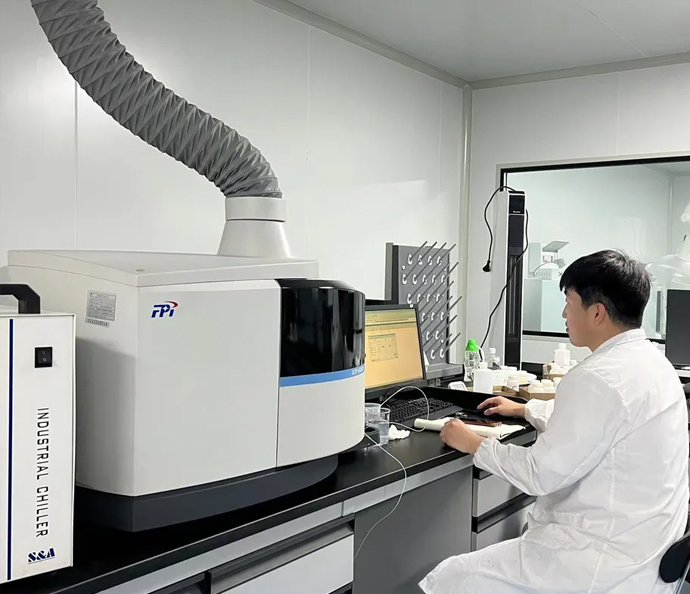

Technical Support:

|

|

Production strength

Key words:

Fortune、chemicals

Online consultation

Filling in your phone and email information will help us get in touch with you in a timely manner and resolve your issue as soon as possible.

Related Products

![CAS 5995-42-6 HEMPA [[(2-hydroxyethyl)imino]bis(methylene)]bisphosphonic acid CAS 5995-42-6 HEMPA [[(2-hydroxyethyl)imino]bis(methylene)]bisphosphonic acid](https://omo-oss-image.thefastimg.com/portal-saas/pg2024092717483878973/cms/image/c3603fb6-9fba-45f6-94a0-da817870459e.jpg)