Hunan Fortune welcomes you!

New Efficient Lead & Zinc Ore Collector

Category:

Sample: provided

Place of original: China

Product Introduction

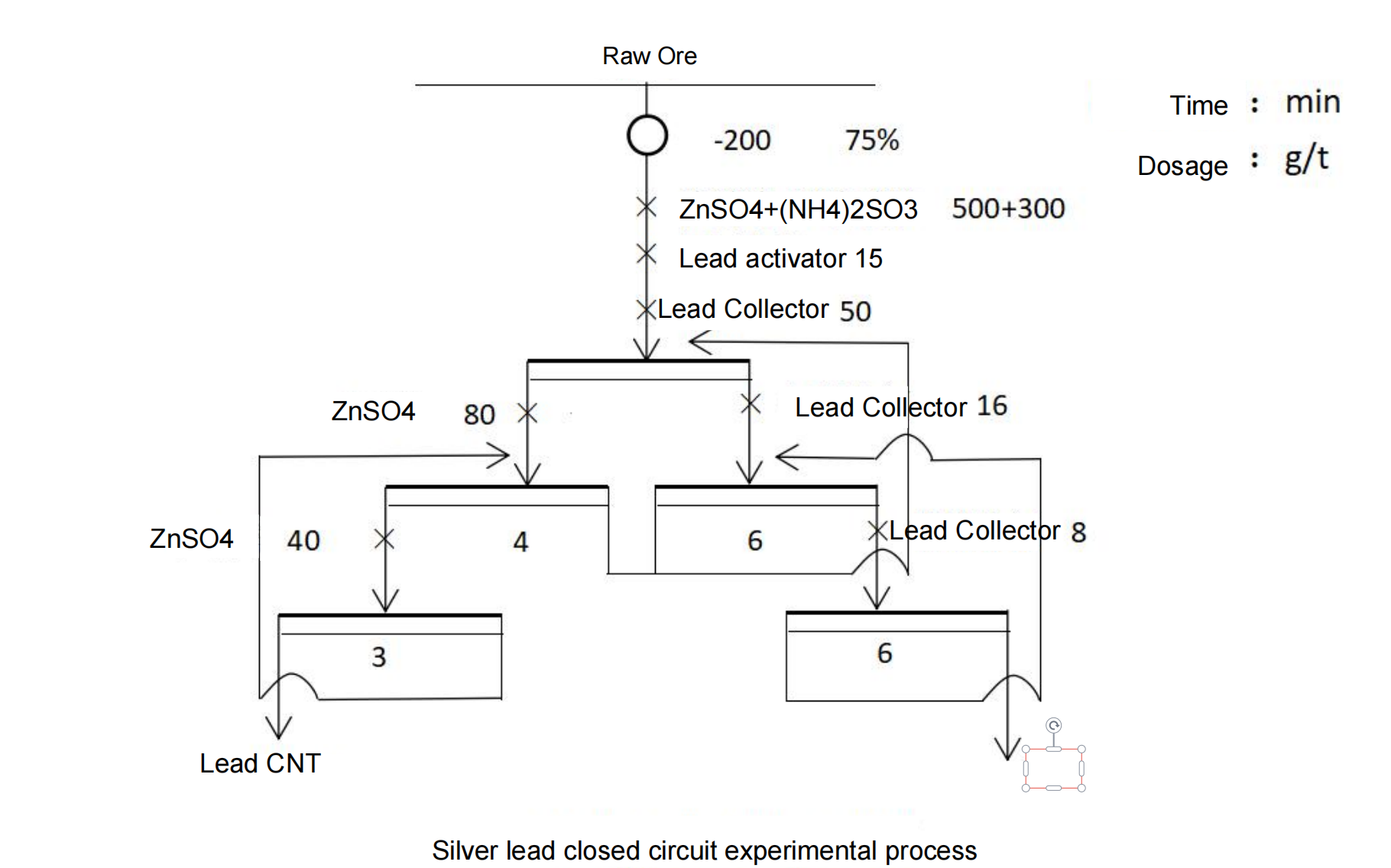

Table 1 Test results of new collector silver lead ore

| Reagent | Samples | Productivity/% | Grade/% | Recovery Rate/% | ||

| Pb | Ag(g/t) | Pb | Ag | |||

| Fortune agent | Pb-Ag CNT | 3.44 | 50.23 | 4905.96 | 90.86 | 93.52 |

| Tailings | 96.56 | 0.18 | 12.12 | 9.14 | 6.48 | |

| Raw Ore | 100 | 1.9 | 180.47 | 100 | 100 | |

| Original agent | Pb-Ag CNT | 3.06 | 50.56 | 4829.34 | 86.46 | 85.58 |

| Tailings | 96.94 | 0.25 | 25.68 | 13.54 | 14.42 | |

| Raw Ore | 100 | 1.79 | 172.67 | 100 | 100 | |

According to the test data in Table 1, compared with the original pharmaceutical process, under the new silver lead collector system, the recovery rate of lead in the concentrate increased by 4.4 percentage points and the recovery rate of silver increased by 7.94 percentage points.

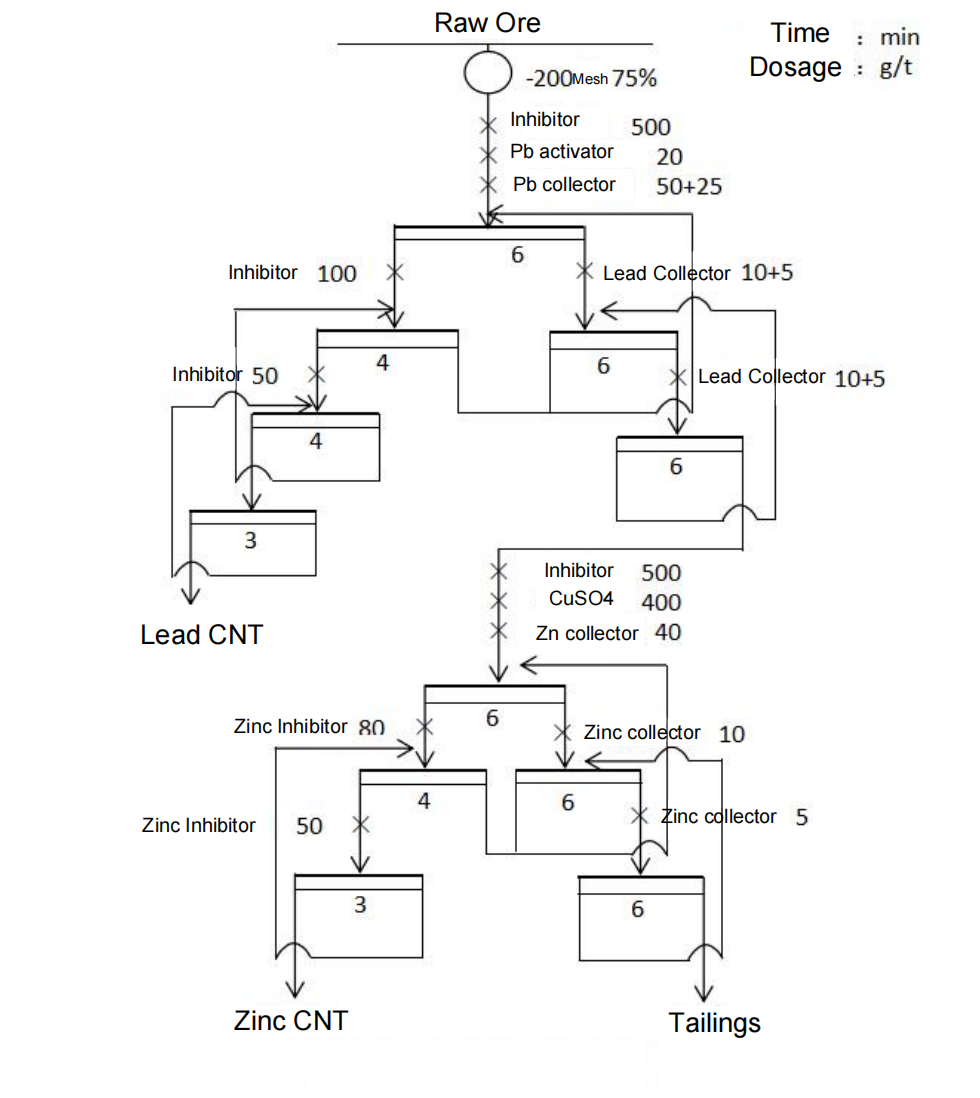

able 2 Test results of lead-zinc ore with new collector

| Reagent | Sample | Productivity/% | Grade/% | Recovery/% | ||

| Pb | Zn | Pb | Zn | |||

| Fortune agent | Lead CNT | 3.56 | 53.86 | 2.63 | 89.21 | 1.57 |

| Zinc CNT | 12.48 | 0.57 | 44.67 | 3.29 | 93.51 | |

| Tailings | 83.96 | 0.19 | 0.35 | 7.5 | 4.92 | |

| Raw ore | 100 | 2.15 | 5.96 | 100 | 100 | |

| Original agent | Lead CNT | 3.41 | 53.36 | 2.53 | 84.33 | 1.46 |

| Zinc CNT | 11.99 | 1.2 | 44.32 | 6.66 | 89.82 | |

| Tailings | 84.6 | 0.23 | 0.61 | 9.01 | 8.72 | |

| Raw ore | 100 | 2.16 | 5.92 | 100 | 100 | |

According to the analysis of test data in Table 2, it can be seen that under the new lead and zinc reagent system, the recovery rate of lead in lead concentrate and zinc concentrate increased by nearly 5 percentage points and 4 percentage points respectively.

Features

At present, lead-zinc sulfide ore usually adopts high alkali preferential flotation process, which is characterized by "strong pressure pulling", and realizes selective flotation of lead and zinc minerals by adding a large number of inhibitors such as lime and zinc sulfate. However, silver and other rare and precious metals are easily inhibited in the high alkali process, resulting in low silver recovery and serious waste of resources. To solve this problem, the company has developed a lead activator FFA-357B and zinc collector FFA-355Z for alkali free or low alkali lead zinc flotation process.

Technical Index

(1) Lead sulfide highly efficient activator FFA-357B Lead sulfide mineral efficient chelating collector, white to light yellow solid powder, environmentally friendly products, mineral processing active component content ≥90%, in the flotation process can significantly strengthen the collision and adsorption of copper lead minerals and collectors, greatly improve the recovery of lead metal processing metal, generally can be increased by more than 3%, The general dosage is 5~20g/t, which greatly improves the mineral processing activity of lead minerals and greatly promotes the flotation recovery; The ability to collect zinc and iron sulfide is weak, and the selectivity is high.

(2) Zinc sulfide ore efficient ring collector FFA-355Z Sphalerite/ferrosphalerite environmental protection and efficient collector, yellow to dark yellow liquid, environmentally friendly products, mineral processing active component content ≥90%, compared with traditional xanthate, sulfur and nitrogen collectors, the actual production amount is xanthate, sulfur and nitrogen collector 1/3, generally in 10~60g/t, The collection capacity of sphalerite/ferrosphalerite is stronger, while the flotation capacity of pyrite/pyrrhopyrite is weak, and the selectivity is extremely high. The amount of copper sulfate used for activation is also significantly reduced, which is conducive to reducing the cost of the agent, and avoiding the odor generated by the configuration of solid xanthates, and the liquid form is convenient for the direct addition of the stock solution in the pipeline.

Application Case 1- a silver lead mine in Henan

Application Case 1- a silver lead mine in Henan Case 2- A lead-zinc mine in Hunan Province

Company Profile:

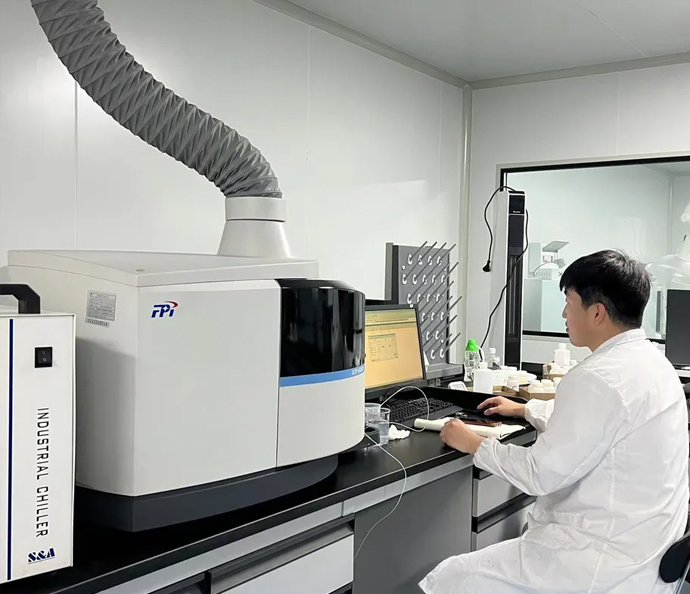

Hunan Fortune Technology Co., Ltd., established in 2004 and officially registered in 2016 with a 30 million RMB capital, is a leading provider of fine chemicals with nearly two decades of industry experience. Based in Zhuzhou, our company specializes in research and production of high-quality chemical agents, including mining chemicals, for environmental solutions and metallurgical processes.

Our team of chemical engineers, with over 20 years of metallurgical expertise, ensures we offer customized solutions and premium products to meet diverse client needs. We have expanded our services to include mining chemicals, enhancing efficiency and sustainability in the mining sector.

With a strong commitment to innovation and sustainability, Hunan Fortune Technology Co., Ltd. is dedicated to providing effective and reliable environmental solutions, contributing to a greener future.

|

|

|

Technical Support:

|

|

Production strength

Key words:

Fortune、chemicals

Online consultation

Filling in your phone and email information will help us get in touch with you in a timely manner and resolve your issue as soon as possible.

Related Products

![CAS 5995-42-6 HEMPA [[(2-hydroxyethyl)imino]bis(methylene)]bisphosphonic acid CAS 5995-42-6 HEMPA [[(2-hydroxyethyl)imino]bis(methylene)]bisphosphonic acid](https://omo-oss-image.thefastimg.com/portal-saas/pg2024092717483878973/cms/image/c3603fb6-9fba-45f6-94a0-da817870459e.jpg)